|

|

|

| |

|

| |

A. It has exceptional mechanical property

① Because it has a yield ratio greater than 90% which is far higher than the 80% required

in PC steel materials, the quality of concrete is outstanding.

② Because the relaxation loss caused by internal stress loss value within concrete products

after inflicting pre-stress at high temperatures, it is economically advantageous.

B. It has good adhesive power with concrete.

Because it has strong adhesive power as 3~6 spiral specks are scooped out uniformly at the surface, the job performance is improved as well as reducing manufacturing costs as mounting devices become unnecessary.

C. It is easy to use.

① Because it enables spot welding using automatic knitting machines without lowering

mechanical properties, it contributes to the improvement of productivity by

raising the quality of concrete products through automation.

② Because the perfect straight line is maintained while unwinding from the coil by

winding as inner coil diameter of greater than 2m within elasticity limit, a separate

correction operation isn’t necessary.

③ Because it is a product manufactured by performing high frequency heat treatment after

heteromorphic imprint of wire rod, it consistently stretches during tension

operations because the precision of value is high and cross section is uniform.

|

|

| |

|

| The specification and mechanical properties of low-relaxation HIBON is same as JIS G 3137 D Type No.1 and the PHC pile in which only the relaxation value among these performs autoclave cure is considered so that it is designed and manufactured to maintain excellent quality features under high temperature. |

|

|

| *Relaxation value is one that has tested 70% of lowest tensile weight as initial weight load for 23 hours. |

| |

|

| |

1) AC Technique

The technique of performing steamed curing at maximum of under 90℃ (mostly 75℃) for

first curing and performing high temperature and pressure curing at maximum of under

200℃ (mostly 180℃). It has the advantage of productivity being raised by not getting

restrictions of manufacturing equipment followed by anti hardening and the forwarding is

possible within a short period of time because curing time is shorter than NAC technique.

② NAC Technique

The technique of performing both first and second curing at maximum of under 90℃

(mostly 75℃) and has the advantage of internal stress loss of steel materials

from elasticity variation and creep, etc of concrete are less while importing relaxation loss

or pre-stress as well as having outstanding inner structure of concrete such as

chemical resistance because of the delicate hydrate structure. |

|

| |

|

| A. Specifications |

(Unit Weight is reference value) |

|

|

| * The allowed margin is for basic diameter |

| |

|

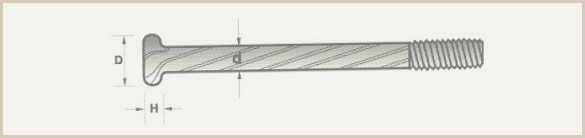

| The HIBON can be performed by warm formation with a head screw without cutting the surface. The value is as follows, It is ideal for working conditions to use after performing intensity conformation after head formation processing with head or warm formation.

|

|

| Reference Value of Screw and Head Sections Size of nut

|

|

| |

|

|

|

| |

|

| Because the most ideal product that can satisfy customers can be manufactured if the purpose and working conditions of the product are clear, Please inform us in detail by referring to the following items. |

|

1. Specification: JIS G 3137D Type or C Type

2. Diameter: Mark both title and official diameter

3. Surface condition: Mark existence of anticorrosion

4. Film: Mark bondelight or borax

5. Usage: Mark the usage specifically(Spring or rolling)

6. Package: Mark as coil packaging or carrier packaging.

7. Weight: Mark required unit weight by packaging type

8. Delivery: Mark desired delivery date

9. Other: Mark other special requirements (Ex: Packaging Method)

|

| |

|

|

|